Why Caesarstone?

Why Caesarstone?

Caesarstone Ltd. manufactures premium quartz surfaces, which are used in both residential and commercial projects as countertops, vanities, wall cladding, floors and other interior surfaces.

Caesarstone combines beauty with outstanding performance, enabling you to bring your design imagination to life.

Why quartz?

Quartz is more than beautiful. It is also one of nature’s hardest minerals. Containing up to ~90% natural quartz, Caesarstone surfaces combine practicality with stunning design

-

Durable

Quartz is more durable than most stone, marble and granite. It is impervious to stains, scratches and cracks, and is highly heat and cold resistant.

-

Scratch & stain resistant

Our quartz surfaces are extremely hard-wearing and will withstand virtually all the challenges of everyday life.

-

Easy care and maintenance

Caesarstone surfaces don't need sealing, treating, polishing or any other form of maintenance, except a simple wipe clean with regular detergent and water.

-

Easy to install

Caesarstone quartz surfaces are highly adaptable and can be cut to fit nearly any space. Just ask your local certified Caesarstone fabricator for the best installation advice.

-

Design flexibility

With the cool, tactile qualities of Caesarstone, you can create a huge range of designs – curved, shaped and many others. Caesarstone lets you free your imagination.

Manufacturing process

Caesarstone surfaces meet exacting standards of excellence from the initial procurement of raw materials to the final quality control check. Highly skilled and trained staff ensure the quality of a product that is unrivalled in the industry today. The manufacturing process begins with a rigorous inspection of all incoming raw materials. These are blended at a ratio of up to ~90% natural quartz aggregates with pigments and polymer resins. Caesarstone quartz surfaces and countertops are manufactured through a highly automated, yet strictly monitored process that includes the following steps:

-

Feeding and mixing

The raw materials (quartz, pigments and polymers) are carefully selected, tested and then mixed together.

-

Moulding and pressing

The mixture is then poured into a mould and formed into slab sizes of 306 x 144 cm or 120 x 57 inches. It is compressed under very high pressure (nearly 100 tons psi) and vibrated in a vacuum. This removes all the air and creates a compressed surface.

-

Curing

The slabs are then moved to the curing kiln and heated to 90°C for 45 minutes which provides the finished levels of strength and solidity.

-

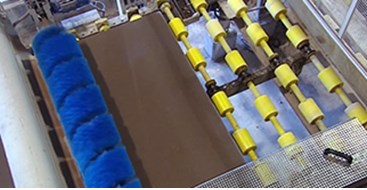

Polishing

The slabs are gauged, calibrated and then polished to a perfect finish in a wide range of colours and designs.

-

Quality Testing

Every slab then undergoes rigorous quality testing to ensure it meets our extremely high standards of color, hue and consistency.

-

Tagging

The slabs are then labeled, sorted and tagged, and enter our distribution system to ensure they reach our customers in perfect condition.